| |

|

|

|

|

>ENGLISH

|

Yangling Red Mulberry Fruit

Food Technology Co., Ltd. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Brief Introduction Located in Yangling Agriculture Hi-Tech Industries Demonstration Zone of China, Yangling Red Mulberry Fruit Food Technology Co., Ltd. is a member of ¡°Sino-France Food Processing Research Exchange Center¡±. The company was initiated by Sun Xueyi, professor of Northwest Sci-tech University of Agriculture and Forestry. At present, it is a hi-tech enterprise with independent property right which boasts various patent and technology including invention, practical new type and deep-processing for the latest farm product. The company has processing mechanical institute of farm product, machinery manufacturing factory and the processing plant of fresh fruit and vegetable juice, with 8 senior engineering technicians and 21 intermediate technical and managerial personnel, and boasts standard production condition and management level. The major products include patent product ¡°Removable processing equipment for fresh fruit and vegetable juice¡± (Invention patent No.ZL02114403.6), raw juice of mulberry, strawberry, cherry, vegetable and concentrate juice, etc. The juice has been exported to countries and regions like Korea, Japan, Britain, America, Switzerland and Taiwan, The company enjoys good fame and credit for its good quality. Established in 2002, the company, through means of exchange, cooperation with enterprise of beverage, wine, medicine, natural pigment and processing of farm product, rapidly developed and has become one of the most excellent enterprises in the field of manufacturing processing equipment of NFC juice concentrated from fresh fruit and vegetable and production of fresh fruit and vegetable juice in China. In the progress of development, we deeply understand the importance of trade partner and supporting from all circles of society. In the future, we are determined to further joint with institutes including College of Food Science and Engineering of Northwest Sci-Tech University of Agriculture and Forestry, Department of Food Engineering of Shaanxi Normal University, College of Life Sciences and Engineering of Shaanxi Science and Technology University, Research Center of Shaanxi Fruit and Vegetable Deep-Processing Technology and Xi¡¯an Design Institute of China Light Industry, etc., to fully take the advantage of science and technology our enterprise, and decide to offer the consumers at home and abroad the most advanced processing equipment of fresh fruit and vegetable juice and series product of NFC juice concentrated from fresh fruit and vegetable in 21st century. Juice |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

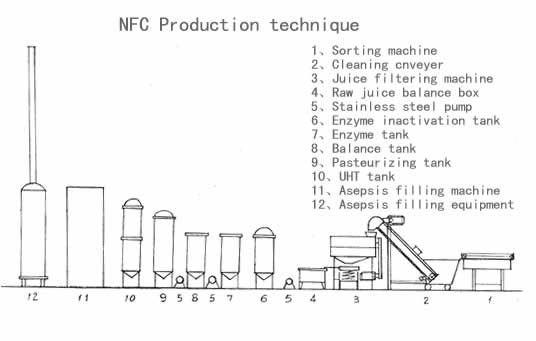

This set of fresh fruit and vegetable

machining equipment is invented by the senior engineer Sun Xueyi

from the Yangling Red Mulberry Fruit Food Technology Co., Ltd. It

solves the problems of fruits such as strawberry, raspberry, mulberry,

cherry, grape and fructus hippophae being hard to transport, to

preserve as well as unable to be processed in the original producing

area. Therefore, this set of equipment is the real NFC fresh juice

plants. This set of equipment is not only an innovation in the field

of fruit and vegetable machining but also a benefit contributor

to society and ecology. The design features are as follows: 1. Complete in function of handle system: The complete set of equipent includes fruit box, cleaning, transportation, extraction, sorting, enzyme inactivation, pasteurized, UHT super high temperature instantaneous sterilization, electron measurement, asepsis filling and electric control device and special boiler as well as manual hydraulic pressure forklift of 1.5ton, It realizes the requirement of enzyme inactivation, asepsis, and asepsis filling after the fresh fruits and vegetables processing to be the fumet nearby, make the mulberry, strawberry can be processed to juice in producing area. This step can make the value added. The fruit and vegetable of 1ton to 1.5 ton can be processed per hour. 2. Movable and compact in structure: According to the characteristics of field work and can be movable, the entire structure adopts the low land gap multi-hanging structure is adopted for the entire. In the Non-working condition, it is made up of four separate underpans and affiliated devices; for each separate underpan there are running gears, which can be installed in the autocar for long-distance transportation by manual forklift, and quite convenient in draught and movement. In the transferring condition, 8.0¡Á2.2¡Á2.4(m), in the working condition 9.6¡Á3.6¡Á8(m), the weight of the structure is 3.8T, the installed capacity is 22KW, the disassembling and assemblage need 2 to 3 hours, the assemblage can be finished within 5.5 hours. 3. Low processing cost in the producing area: As fruits and vegetables are purchased, near the producing area,, the raw fruit juice has good quality and high producing rate of fruit juice (taking the grape as an example, its producing rate of fruit juice reaches 85%), and the expense of packing, transfer, reservation and long-distance transportation are saved, the loss from damage and rot during the progress of transfer is avoided, all of which greatly decrease production cost and increase market competitive force of the product. 4. Industry chain in positive circulation: As fruits and vegetables are purchased, stored and processed to raw fruit juice near the producing area, raw fruit juice residues can be used as feedstuff, the water after washing the fruit without the acid and alkaline can be used to irrigate the farmland, which are help for the civilized production of juice processing plant. 5. Without antiseptic in the product: As fruits and vegetables are purchased, stored and processed to raw juice near the producing area,, which insure that the completeness and greenness of the material needed for raw fruit juice production, maintain nourishment component, color, fragrance and flavor of the fruit to great extent; as the technology of pasteurized, UHT sterilization and asepsis filling are adopted during the processing progress. The products are green product without any antiseptic, It can be exported to make large profit in foreign currency. 6. Good benefit from multi-purpose machine: According to different requirements of users, this production line can process the fumet of different fruits and vegetables through collocating different pre-processing equipments, For examples, process cherry in April, strawberry and mulberry in May, fresh apricot in June, tomato in July, grape in August, fructus hippophae and Chinese goosebeery in September and October, and other stored acinus and vegetable can be processed in the period of from November to March of the next year. When the production line takes the juice extractor off, it also can meet the requirement of purchasing, asepsis and asepsis filling for fresh milk and goat's milk in a pasturing area and other producing places, and also ensure the color, fragrance, flavor, and nutrition component of them. In brief, the effective working day every year is over 300 days. With good organization and operation, the cost shall be refunded in the current year and a rich profit shall be acquired. Production technique: Purchasing in producing area ¡úon-spot extraction¡ú enzyme inactivation asepsis ¡úUHT sterilization¡úelectron measurement¡ú asepsis filling  |

| Yangling Red Mulberry Fruit Food Technology Co., Ltd.

Room,3rd building,No 12 of east section of Long Shou Bei Lu, Xian,Shaanxi,China tel:0086-29-86248395 fax:0086-29-86248395 mobile £º0086-013088962323 mobile £º0086-013227856902 postalcode :710015 Email:Yanglhsg@sina.com http://www.sangshen.com |